What kind of methods to determine component failures?

What kind of methods to determine component failures?

It is possible to identify defects with several tests. Failure analysis helps to understand the faults and their prevention, which improves both the production as well as assembly processes. Here are a few important ones:

1.Solderability test

Solderability defines the wetting of a metal or metal alloy surface by solder under minimum adequate conditions. Usually, the board manufacturing process itself is the cause of assembly difficulties. It is due to problems associated with oxidation and improper application of the solder mask. To reduce this failure, check components and pad solderability to ensure the robustness of the surface. It also helps to develop a reliable solder joint.

This testing assesses the strength and wetting quality of the solder by replicating the contact between the solder and the material. It determines the wetting force and the duration from contact to wetting force formation. Moreover, it identifies the cause of the fault. Applications of solderability testing include:

--Evaluation of solder and flux

--Circuit board coating evaluation

--Quality control

To effectively utilize this testing, it is crucial to understand various surface conditions and adequate requirements of the testing method.

2.Contamination test

Contamination induces various problems such as corrosion, metallization, and degradation. The circuit board has to go through aggressive chemical solutions within its lifecycle. Such chemicals include etching liquid, fluxes, electrolytic solutions, etc. It is necessary to perform cleaning after the application of these chemicals.

Contamination testing calculates the number of ionic contaminants present in the sample. This process involves immersing the circuit board into a sample solution. This solution dissolves the ionic impurities that change the composition of the solution and the values. Then, by comparing the actual level with the standard level, it is possible to analyze the severity of the contamination. There should be a focus on the cleaning process to avoid the risks of failures.

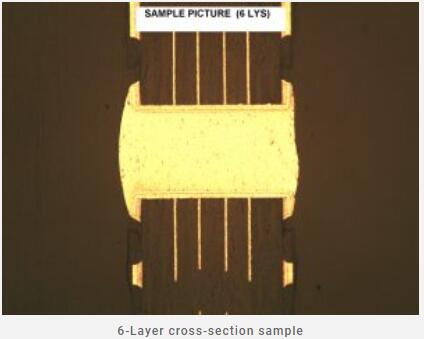

3.Micro-sectioning test

The micro-sectioning test, also known as cross-sectioning, inspects the following:

--Component defect

--Shorts or opens

--Thermo-mechanical breakdown

--Solder reflow processing failures

--Analysis of raw materials

In this method, a two-dimensional slice is cut out of a sample which reveals the board’s features. The micro-sectioning analysis is a destructive testing method that provides an accurate way to separate electronic components and remove them from the sample. Then, it is placed in epoxy resin for curing and solidifying. Later, using an abrasion technique, the component is removed and then polished until it is reflective. This test involves a comparison of this sample with the functioning part.

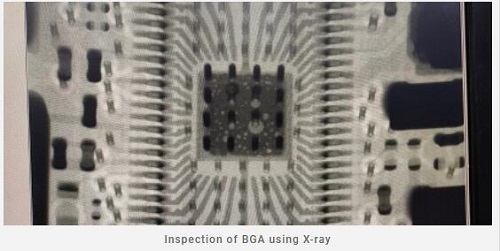

4.Automated X-ray inspection (AXI)

Automated X-ray inspection (AXI) determines hidden defects related to ICs and BGAs in PCBs. This method accesses internal geometries and structural compositions. The following errors can be detected using this method:

--Soldering defects like opens, shorts, solder bridges, solder voids, excess and insufficient solder, and solder quality.

--Component defects like lifted lead, missing component, and misplaced component

--BGA errors including BGA shorts and open circuit connection

5.Surface imaging method

One of the most popular testing methods for finding problems related to soldering and assembly is optical microscopy or the surface imaging method. The technique is popular due to its efficiency and accuracy. It uses a high-power microscope with visible light. This microscope features small depth field and one-plane view and can reach a magnification of 1000X. It can verify improper construction, which causes stresses that expose flaws in some cross-sections.

Know more:

What is electronic component failure in PCB?

Common electronic component failures in PCB?

PCB Blog

Contact Us

E-mail: [email protected]

E-mail: [email protected]

Skype: [email protected]

Whatsapp: +86 15012972502

Add: 2F, BUILDING H, WANDA INDUSTRIAL ZONE, ZHOUSHI ROAD, LANGXIN COMMUNITY,SHIYAN STREET, BAO 'AN DISTRICT, SHENZHEN, GUANGDONG, CHINA

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry