What is Popcorn Effect During PCB Assembly Process

What is Popcorn Effect During PCB Assembly Process

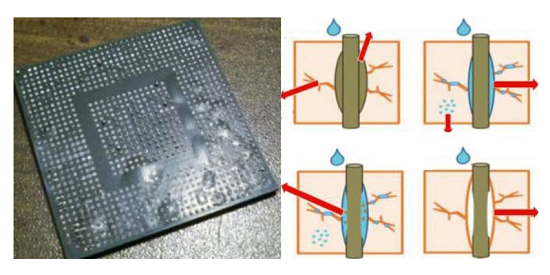

In short, the popcorn effect is when the IC or BGA blows up or even breaks because the dampness inside the bundle grows in the reflow interaction.

To be more detailed, we need to mention plastic exemplified microelectronic devices used in airtight parts. During the PCB assembly process, dampness in a plastic bundle can disintegrate under high temperatures and apply weight to the bundle. This pressure makes the bundle break and furthermore causes delamination between the shaping compound and the lead casing or bites the dust.

Patch ball inside with lead measure and outside with sans lead may bring about disappointment. It is provoked by the softening mark of lead and without lead material, and this is distinctive in a similar ball grid array (BGA) packaging chip. In most serious cases, the packaging surrenders and the pressure may bring about outer bundle breaks. Furthermore, the BGA packaging chip has a void in the joint interface, where dust appends, and this leads to a short out between certain pins.

How to detect the popcorn effect?

The extension can result in the bite of the dust or harm to the substrate or wire securities. The harm is regularly undetectable and requires X-beam hardware to lead an appropriate examination.

PCB Blog

Contact Us

E-mail: [email protected]

E-mail: [email protected]

Skype: [email protected]

Whatsapp: +86 15012972502

Add: 2F, BUILDING H, WANDA INDUSTRIAL ZONE, ZHOUSHI ROAD, LANGXIN COMMUNITY,SHIYAN STREET, BAO 'AN DISTRICT, SHENZHEN, GUANGDONG, CHINA

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry