Industrial

Industrial PCB assembly

PCBs are an integral part of life today, Over the years, industries have witnessed a lot of progress in terms of automation and hence the industrial electronics market has grown rapidly. With this, the demand for industrial PCBs has gone up.

Electronics used for industrial applications need to be very stable, durable to fit in extremely harsh conditions, at the same time maintaining long service lives. Industrial PCB designs and Industrial printed circuit board manufacturing also need to follow strict industrial SIL and IEC standards and create unique design features and form factors for any industrial settings.

Industrial customers may have 300 different PCBs but each model only need two to three hundred piece each time, these types of orders just matched by our expertise and production schedule,our prototype plant are just suitable for your high-mix, low-volume needs.

Applications of Industrial Electronics PCBs

Here are a few application areas of industrial electronics PCBs:

1.Mini computer

2.Batteries

3.Diode testers

4.Converters

5.Amplifiers

6.Analog meters

7.Drive motors

8.Feedback devices

9.Fuses

10.Input output modules

11.Indicators and displays

12.LED lighting systems

13.Microprocessors

14.Panel meters

15.Overload relays

16.Power monitoring systems

17.Potentiometers

18.Power supply units

19.Robotics

20.Electronics switch gears

21.Industrial drives & inverters

22.Electronic test & measurement equipment

23.Energy control system

24.Industrial smart meters

25.Electronic smart labels

26.Industrial lighting systems

What is Industrial PCB?

Firstly, a PCB (printed circuit board) is an internal component that mechanically supports electronic parts.An industrial PCB, in this case, is a PCB built for and used in industrial applications.It is a component made of several layers of insulating material combined with electrical conductors.

Commonly, the insulator is made of various types of material which can often be based on fibreglass, plastic or ceramics.When a PCB is created, the manufacturing process will etch off various sections of the PCB to leave one completed printed circuit board that can be used with an electronic component.Understand that PCBs are the backbone of every electronically operated equipment.

A lot of modern technology could not exist without a PCB in place.In other words, industrial PCBs are integral to the smooth, productive operation of any industrial electronic equipment.

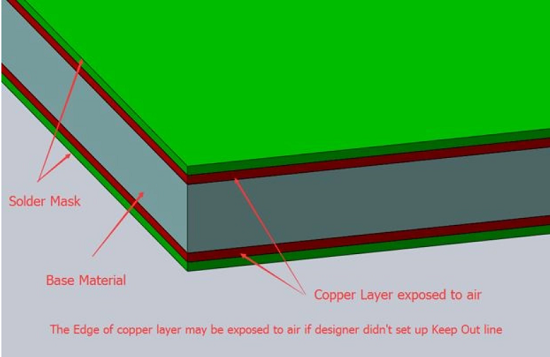

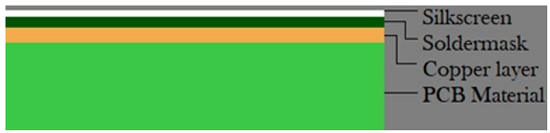

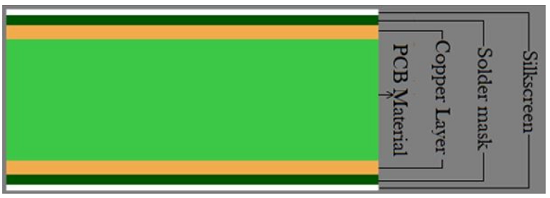

Composition of Industrial PCBs

An industrial PCB resembles a layered cake.It constitutes alternating layers of different materials that are laminated together with heat and adhesive.The result?A single object that we refer to as a printed circuit board.

Types of Industrial PCBs based on layers

1.Single layer PCB

Single layered PCBs are the most typical circuit boards in the market. They are built with a single layer or base material.The single layer is coated with a conductive material like copper.They may also have a silk screen coat or a protective solder mask on top of the copper layer.

A significant advantage of this type of PCB is the low production cost.It is, however, suitable for use in applications that require very basic circuitry which is not so common in industrial applications.

2.Double layer PCB

Double layered PCBs hold circuits that are slightly more intricate than single layered ones.They are much like single layered boards only that these have the conductive material on both sides.The good thing with double sided boards is that they can hold slightly complex circuits.

This type of board also increases operational flexibility and is a practical option for building more dense circuit designs.Note that although advantageous in many aspects, double-sided boards aren’t a viable option for the most complex circuits.

They are unable to work with technology that reduces electromagnetic interference.This is why they are commonly used in amplifiers, power monitoring systems and testing equipment.

3.Multilayer PCB

For complex circuit systems, multilayer PCBs are most suited.These are boards that feature multiple sheets of substrate with insulating layers in between each sheet.Depending on the complexity of a circuit, such PCBs can range from 2 to 4 to 8 layers.Highly sophisticated circuits feature boards with up to 42 layers.

Types of industrial PCBs based on rigidity

You should understand that different industrial applications need different types of PCBs.And, apart from layers, industrial PCBs can also be differentiated by their rigidity.The three types of PCBs based on rigidity are;

1.Rigid PCB

These are boards built with rigid, non-flexible material for its layers.The material makes the board unable to bend beyond a specific limit as it will crack or break.Rigid PCBs are typically compact and can handle complex circuit designs.Plus, the signal paths in rigid PCBs are easy to organise, and the ability to maintain and repair is quite straightforward.

2.Flexible PCB

This is another common type of industrial PCB on the market.The circuits in flexible PCBs are assembled on a thin, flexible insulating material.Flexible PCBs note is very versatile.They are not just designed with a flexible layer but are also available in single, double or multilayer board.

These type of circuits are a great option when it is necessary to save space and weight when building a particular device.Also, they are appreciated for high ductility and low mass. However, the flexible nature of the board can make it more difficult to use.

3.Rigid-flex PCBs

These are a combination of rigid and flexible PCBs.

The circuits are mostly used in applications where a very dense circuit is required such as in aerospace and military.Rigid-flex PCBs help save a significant amount of space, resulting in electronic products that weigh much less.As earlier mentioned, printed circuit boards are manufactured in various types to suit the varying needs of the industry.For this reason, you have to choose a PCB that is utmost suitable for your industrial equipment.

If you’re not sure which type is best suited for your application, consult with your supplier or PCB expert for advice and recommendation

Best Materials for Industrial PCB

Before choosing a PCB for your industrial application, it is essential that you consider what the best materials for it are.

After all, the resilience and strength of the chosen material will have a direct impact on the PCB’s capability to support its intended application.Ideally, industrial PCBs should feature a strong foundation for which the PCB traces and components can be etched.As mentioned severally in this guide, there are a variety of possibilities when it comes to PCB materials.However, the most popular ones for industrial PCBs tend to be fibreglass, metal and Teflon.

There are three key elements of consideration when choosing Industrial PCB materials.

1.Quality

Regardless of a PCB’s intended use, its material must meet certain basic requirements.

For instance, the board must have a good time to delamination. This is so that its integrity isn’t easily compromised by physical stress.Excellent quality PCBs also allows you to perform hardware updates without compromising the components of the original PCB board.

2.Cost

For cost, understand that there is a great variance depending on several factors.For instance, Gold tabs tend to be more expensive than solder tabs.

Also, when considering blind vs. buried vias, the latter is cheaper.The same applies to line/width spacing. Spacing above 6mm incurs higher costs than when using a below 6mm spacing.

3.Power and heat

The thermal capacity of industrial PCB material are crucial in determining a PCB’s usefulness and reliability.As such, always ensure that you check the thermal capacity of your chosen PCB material.Also, you need to know the rate at which the material turns wattage power into temperature.

|

|

Total: 1

Page: 1 / 1

First

←Previous

Next→

End

|

Contact Us

E-mail: [email protected]

E-mail: [email protected]

Skype: [email protected]

Whatsapp: +86 15012972502

Add: 2F, BUILDING H, WANDA INDUSTRIAL ZONE, ZHOUSHI ROAD, LANGXIN COMMUNITY,SHIYAN STREET, BAO 'AN DISTRICT, SHENZHEN, GUANGDONG, CHINA

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry