Products >> Single sided PCB assembly

Single sided PCB assembly

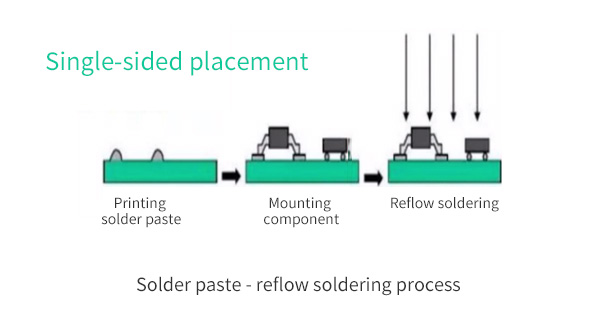

1.Single-sided SMT placement

*Add solder paste to the component pad, after the tin printing of the PCB board is completed, reflow soldering the electronic components, and then reflow soldering.

*Single-sided SMT Process:

Incoming Inspection => Screen Solder Paste Printing(Dispense surface mount adhesives) => Surface Mounting => Drying(Solidifying) => Reflow Soldering => Clean out => VI&AOI => Rework/Repair.

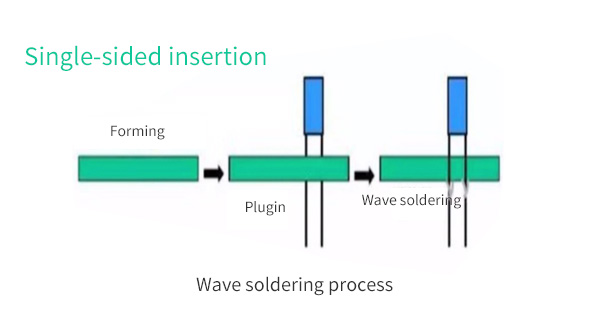

2.Single-sided DIP cartridge

The PCB board that needs to be plugged in by the production line workers inserts the wave soldering of the electronic components. After the welding is fixed, the foot cleaning can be done, but the wave soldering production has a lower efficiency.

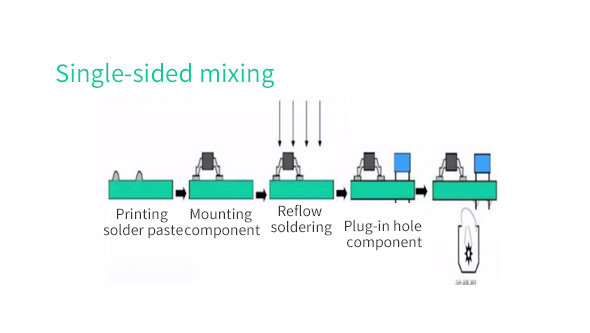

3.Single-sided mixing

*The PCB board is solder paste printed, and the electronic components are mounted and reflow soldered. After the quality inspection is completed, the DIP is inserted, and then the wave soldering or the hand soldering is performed. If there are fewer through-hole components, manual soldering is recommended. *Incoming Inspection => Screen Solder Paste Printing on PCB A side (Dispense surface mount adhesives) => Surface Mounting => Drying(Solidifying) => Reflow Soldering => Clean out => DIP => Wave Soldering => Clean out => VI&AOI => Rework/Repair.

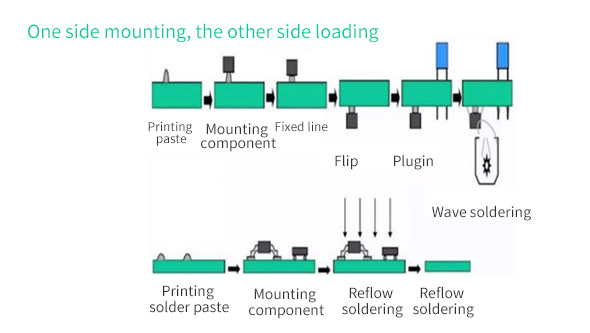

4.Single-sided placement and plug-in mixing

Some PCBs are double-sided rice, one side is mounted, and the other side is inserted. The process of placement and insertion is the same as that of the top surface, but the PCB is reflow soldering and wave soldering.

Why to Keep PCB Single-Sided

Having a double sided PCBA is essentially like having 2 separate PCBs with additional hurdles. This means double the stencils, double the stencil printing, double the programing, double the pick and place, double the reflow, and so on. This leads to the costs of assembly increasing. If your project has a strict budget or lower margins, it might be beneficial to figure out how to make a single sided PCB work. Double-sided PCBs also have additional things to look out for during manufacturing. Since they are run through the reflow oven twice, it is important to look at heavier components possibly falling off on the first side during the second reflow. Heat sensitive components must also be considered as that first side will be exposed to another reflow step (although most parts are built to be able to withstand this). Having heat sensitive components and heavier components on the “second” side of the board may improve manufacturability. If the double-sided board is mixed technology and has through hole components in addition to SMT parts, wave soldering may not be possible and hand soldering will need to be done which means additional costs.

Products Category

- PCB Design & Layout

- PCB manufacturing

- PCB Assembly

- BGA Assembly

- THT Assembly

- SMT Assembly

- Mixed PCB Assembly in Electronic PCBA

- Single sided PCB assembly

- Double sided PCB assembly

- Rigid-Flex Assembly

- COB Bonding Manufacturing

- Components sourcing for PCB Assembly

- SMT Stencils

- Box build assembly

- PCB engineer reverse

Contact Us

E-mail: [email protected]

E-mail: [email protected]

Skype: [email protected]

Whatsapp: +86 15012972502

Add: 2F, BUILDING H, WANDA INDUSTRIAL ZONE, ZHOUSHI ROAD, LANGXIN COMMUNITY,SHIYAN STREET, BAO 'AN DISTRICT, SHENZHEN, GUANGDONG, CHINA

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry