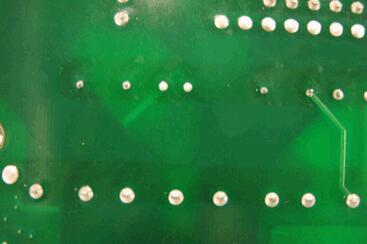

Solder Mask Discoloration on a PCBA Board

Solder Mask Discoloration on a PCBA Board

Dark stripes on the solder mask after selective soldering.

Normally this is a cosmetic issue but should be investigated for the real cause. When running a thicker board it is probable that the soldering process or dwell times may have changed.

The most common reasons for this occurrence include:

1.Different flux used, higher temperature, longer dwell time or boards were run twice in pallet

2.Solder mask/resist type, thickness or cure cycles have changed

3.PCB supplier has been changed, or mixed batches of boards

There is no reference to the board finish, solder alloy being used or flux type - water or alcohol based. These are important when conducting analysis of the process problem.

PCB Blog

Contact Us

E-mail: [email protected]

E-mail: [email protected]

Skype: [email protected]

Whatsapp: +86 15012972502

Add: 2F, BUILDING H, WANDA INDUSTRIAL ZONE, ZHOUSHI ROAD, LANGXIN COMMUNITY,SHIYAN STREET, BAO 'AN DISTRICT, SHENZHEN, GUANGDONG, CHINA

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry