What causes PCB bow and twist?-Rapid Heating During Assembly

What causes PCB bow and twist?-Rapid Heating During Assembly

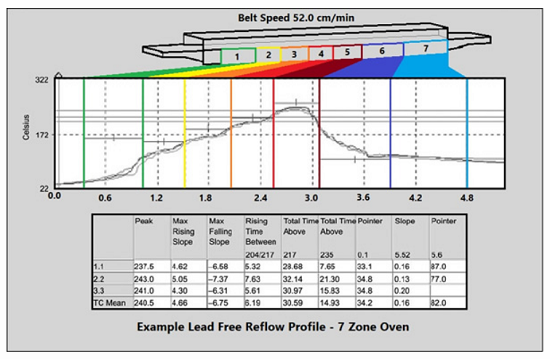

The slower your board is heated during solder reflow the better. This will allow the copper and laminate to expand at closer to the same rate and prevent the board from bowing or twisting. Copper has a higher CTE (coefficient of thermal expansion) than laminate.

A successful lead-free solder process requires higher temperatures and has tighter target ranges for heating, cooling and time spent in each zone. It's recommended to use a reflow oven with as many zones as possible to dial in your reflow profile. An oven with at least 7 zones is recommended for lead free assembly process.

To know more:

What causes PCB bow and twist?-Uneven Copper Distribution

What causes PCB bow and twist?-Unbalanced Stack Up

What causes PCB bow and twist?-Pre-Preg Materials Arranged Incorrectly

What causes PCB bow and twist?-Mixed Material Types

What causes PCB bow and twist?-Finished Thickness

What causes PCB bow and twist?-Moisture

What causes PCB bow and twist?-Rapid Heating During Assembly

What causes PCB bow and twist?-Assembly Conveyor Setup

PCB Blog

Contact Us

E-mail: [email protected]

E-mail: [email protected]

Skype: [email protected]

Whatsapp: +86 15012972502

Add: 2F, BUILDING H, WANDA INDUSTRIAL ZONE, ZHOUSHI ROAD, LANGXIN COMMUNITY,SHIYAN STREET, BAO 'AN DISTRICT, SHENZHEN, GUANGDONG, CHINA

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry