How to Avoid Popcorn Effect in PCB Assembly?

How to Avoid Popcorn Effect in PCB Assembly?

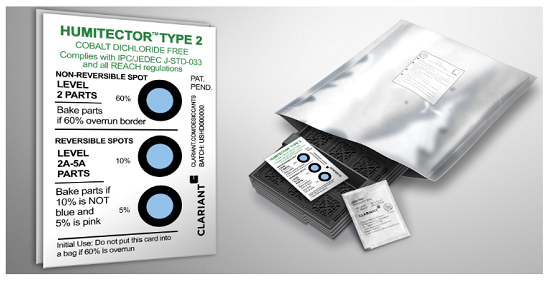

To keep harm from the popcorn effect, plastic epitomized microelectronic devices should be prepared before gathering to drive out the dampness.To maintain a strategic distance from the popcorn effect, basically prepare the devices and seal them in an airtight fixed antistatic pack. Utilize a dampness sign card to guarantee your devices are not transforming into popcorn. It is acceptable practice to investigate the humidity indicator card quickly after opening the parcel and supplanting it with a new card with each utilization.

If the devices were presented to dampness, re-bake them and amass the devices inside the permitted openness time. The baking is driving all the dampness out of the device.

Coming up next are significant focuses to focus on with a moisture control program:

1.Keep a definite record of openness times each time the devices are utilized, and bake if the floor life has been surpassed. Baking resets the clock.

2.Keep up encompassing industrial facility conditions to lessen moisture penetration during dealing with and fastening floor life estimations.

3.Baking occasions for various MSL devices, bundle thicknesses, and baking conditions are changes from one case to another.

4.Higher-level moisture-sensitive level devices must be baked before every use within the specified floor life.

5.Care should be taken to avoid baking for too long or at higher than necessary temperatures to prevent oxidation and the formation of intermetallic compounds in the device.

6.The relevant baking tray for the baking temperature should be used to prevent the formation of gases.

7.The entire board should be baked if the device requires re-working to prevent damage.

The reflow profile should be coordinated to the prerequisites of the patch glue, just as the warm limits of the PCB get together. It is fundamental that exact profiling is accomplished and a precise information recording framework is used Lead-free bind glues don't change the essential standards of weld reflow. They do fundamentally lessen the size of the warm interaction window, and thus make reflow a more basic advance in the sequential construction system, influencing all out-item quality yield.

Tests to Check for Popcorn Effect

One of the significant devices presently used to non-dangerously review the disappointment include came about because of the "popcorn effect" of plastic epitomized microelectronic devices was Scanning Acoustic Microscopy (SAM). Applications included non-destructive identification of delamination between lead outline, pass on the face, paddle, heat sink, breaks, and plastic encapsulant. Also, another ruinous method was cross-segment examination which could approve the aftereffect of SAM assessment and more outwardly present the disappointing appearance. For case one, by C-mode Scanning Acoustic Microscopy (C-SAM) investigation delamination was seen at the interface of the PCB and trim compound at some external bonds. Also, PCB breaks and wire bond breaks could be seen by cross-segment investigation. For case two, C-SAM investigation can detect delamination at the interface that can bite the dust. What's more, die breaks and both wedge bond and ball bond breaks could be seen by cross-area examination.

Moisture-Sensitive Devices

Moisture-sensitive devices (MSDs) are electronic parts epitomized with plastic mixtures and other natural materials. Moisture from climatic mugginess enters penetrable packaging materials by dissemination and gathers at the interfaces of divergent material.

MT LEDs are classed as moisture-sensitive devices (MSD) as per moisture affectability norms. BGA and chip-scale packages are also moisture-sensitive. The popcorn effect may occur to these MSDs. To amplify the creation, yield, and lifetime of the devices, additional precautionary measures should be taken during stockpiling, dealing with, and gathering.

To classify the MSDs’ moisture sensitivity levels, the IPC/JEDEC J-STD-020B and IPC/JEDEC J-STD-033B are the standards to use.

PCB Blog

Contact Us

E-mail: [email protected]

E-mail: [email protected]

Skype: [email protected]

Whatsapp: +86 15012972502

Add: 2F, BUILDING H, WANDA INDUSTRIAL ZONE, ZHOUSHI ROAD, LANGXIN COMMUNITY,SHIYAN STREET, BAO 'AN DISTRICT, SHENZHEN, GUANGDONG, CHINA

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry